Performance Racing Technology

National Speed Sport Association (NASA) views G...

NASA (racing) could have established a world record for the number of Spec Miatas on track at the 2018 NASA Championships Presented by Toyo Tires at Circuit of The Americas....

National Speed Sport Association (NASA) views G...

NASA (racing) could have established a world record for the number of Spec Miatas on track at the 2018 NASA Championships Presented by Toyo Tires at Circuit of The Americas....

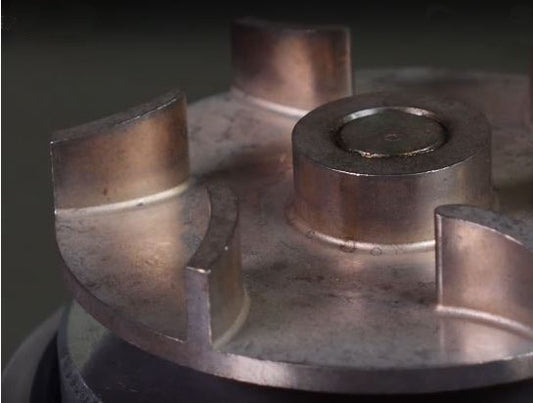

SAVE POWER WITH UPGRADED PERFORMANCE RACING WAT...

The best way to avoid problems when replacing a water pump for racing, towing, street performance, off-road, or a street rod is to purchase a new upgraded water pump from...

SAVE POWER WITH UPGRADED PERFORMANCE RACING WAT...

The best way to avoid problems when replacing a water pump for racing, towing, street performance, off-road, or a street rod is to purchase a new upgraded water pump from...

THE BEST WAY TO IMPROVE POWER OF A SUPERCHARGED...

AFCO's upgraded #heat-exchangers from #APPLIEDSPEED.com are twice as thick as the stock variants. This feat and other cooling techniques developed in professional racing yield a 350% improvement in cooling of...

THE BEST WAY TO IMPROVE POWER OF A SUPERCHARGED...

AFCO's upgraded #heat-exchangers from #APPLIEDSPEED.com are twice as thick as the stock variants. This feat and other cooling techniques developed in professional racing yield a 350% improvement in cooling of...

THE GARMIN CATALYST DRIVING PERFORMANCE OPTIMIZ...

Innovation fosters ideas like creating the automobile instead of a faster horse. Innovators are exceptional visionaries who implement their talents to their visions. In racing, we can argue the merits of...

THE GARMIN CATALYST DRIVING PERFORMANCE OPTIMIZ...

Innovation fosters ideas like creating the automobile instead of a faster horse. Innovators are exceptional visionaries who implement their talents to their visions. In racing, we can argue the merits of...

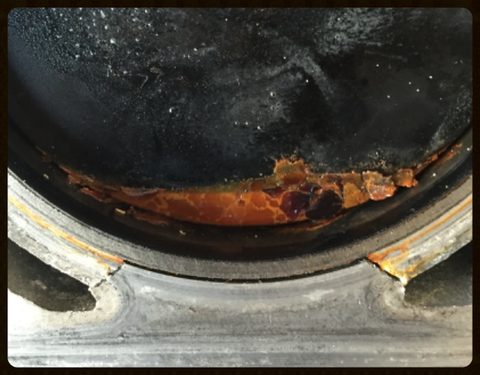

WINTERIZING TO PROTECT YOUR RACECAR, RV, TRUCK,...

Vintage and race cars, weekend time trial or drag cars, Jeeps, Off-Road vehicles, Street Rods, street performance cars, and tow vehicles, when stored in the winter or summer, require some...

WINTERIZING TO PROTECT YOUR RACECAR, RV, TRUCK,...

Vintage and race cars, weekend time trial or drag cars, Jeeps, Off-Road vehicles, Street Rods, street performance cars, and tow vehicles, when stored in the winter or summer, require some...

ROSS BENTLEY TESTS A NEW DRIVER “TRAINING TOOL"

Could it be true that there is a device that can pinpoint instantly where to brake, turn, accelerate, and more? Is this a coach in a box? Is it another book from Ross? Could this...

ROSS BENTLEY TESTS A NEW DRIVER “TRAINING TOOL"

Could it be true that there is a device that can pinpoint instantly where to brake, turn, accelerate, and more? Is this a coach in a box? Is it another book from Ross? Could this...